Alcohol levels in just about everything are rising, and a lot of people aren’t happy about it. Nonetheless, winemakers would really rather you not know that they’re doing something about it. Or, at least, one particular something about it: dealcoholization, or “dealcing.” While there are alcohol-free or very low alcohol wines on the market, what I’m talking about is bringing super-hot 14-17% alcohol wines down to the more comfortable 11-14% range.

![By Valo at de.wikipedia [CC-BY-2.5 (http://creativecommons.org/licenses/by/2.5)], from Wikimedia Commons](http://palatepress.com/wp-content/uploads/2013/01/Flametail.jpeg)

Why alcohol levels are rising is no mystery. Winemakers are working with riper grapes to satisfy contemporary tastes for the big, the luscious, and the fruit-forward. Wine growing regions are warming up so that grapes have the time and sunlight to accumulate sugars like never before. Better yeasts are able to handle both more sugar and more alcohol without giving up, so winemakers don’t have to add water to ensure that high-sugar musts will ferment.

What to do about all this heat is a different matter. You might argue that we shouldn’t do anything about it at all; higher ABVs are a natural consequence of riper fruit, riper fruit is good, and so there we are. But plenty of other people, including a lot of consumers, aren’t happy about seeing numbers in the 14-16% range on their bottles, and a substantial industry has emerged in an effort to make those people happier.

Reducing alcohol isn’t just about pleasing customers who want lower-alcohol wines, though that’s part of it. It’s also about taxes. Both in the United States and the EU, wines with more than 14% alcohol reported on the bottle (labels only have to be accurate by plus or minus 0.5%) accrue higher taxes than wines under that limit. For mega-wineries with lakes of wine to process, “dealcing” to slide below that threshold can save money. And then there’s the “balance” argument; some winemakers feel as though their wine tastes better with super-ripe flavors but less alcohol than that ripeness usually produces. The EU allows winemakers to reduce the alcohol content of their wines by up to two (ABV) percentage points either via the reverse osmosis or spinning cone approach. American winemakers are free to reduce as they please.

A 2006 survey calculated that about 18% of California’s vintage in that year went through a dealcoholizing process. Dealcing is big business, but no one talks about it. Wineries aren’t keen to have their consumers know that alcohol has been removed from their products because most of us don’t want to think about wine as a product at all. Big plastic membranes and metal cones don’t exactly fit in with the romantic view of the sunburnt winemaker carefully tending his vines and checking his barrels in glowing valleys and musty caves. But large wineries are very much industrial food product factories with hardhats and big metal tubes. Dealcing is just one more tool to “dial in” product specifications.

Wineries have a few options when it comes to bringing alcohol levels down:

Adding water

The oldest, but (arguably) least satisfactory method. Diluting high-sugar must obviously doesn’t just dilute the sugar (and therefore the alcohol), but flavor, too. The upside is that this method is very “natural,” but watered-down wines tend to taste…well, watered down.

![By Roger McLassus (Picture taken and uploaded by Roger McLassus.) [GFDL (http://www.gnu.org/copyleft/fdl.html) or CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0/)], via Wikimedia Commons](http://palatepress.com/wp-content/uploads/2013/01/2006-02-13_Drop-impact.jpeg)

Starting with less-ripe grapes

Another old-fashioned option. Less ripe means less sugar, but different and less ripe flavors, too. Now, there’s very much a less-ripe wine fan club (I count myself a member and, if you appreciate reds from the Finger Lakes, you probably are too). But this option really doesn’t work if you don’t want to change the flavors you’re getting with your 15-16% alcohol wines.

Reverse osmosis (membrane filtration)

Here comes the technology. Nearly all large-ish wineries who want to lower their alcohols use one of two techniques: reverse osmosis or spinning cone columns (more about the latter in a moment.) The industry for performing these services has split into two monopolies, with Vinovation dominating the reverse osmosis side of things.

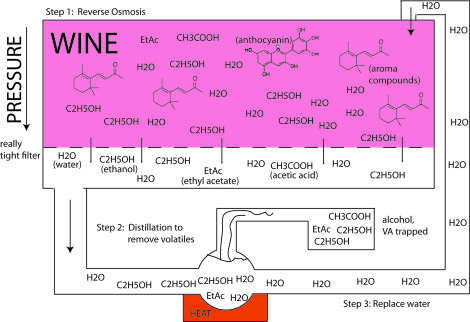

Reverse osmosis (RO) works by putting wine into contact with a membrane – a plastic film – with very, very tiny holes. These holes are so tiny that the only molecules that can pass through, pretty much, are water (H2O) and alcohol (C2H6O). To avoid having the membrane clog up and to make the process more efficient, the wine is run parallel along the membrane rather than perpendicular directly at it. The liquid that passes through the membrane – the “permeate” – can then be distilled to separate the water from the liquid. Measure the alcohol content in the filtered wine, add back water and alcohol in whatever proportion you need to achieve the final alcohol percentage you want, and there you go: “alcohol fine-tuning.” Because flavor molecules tend to be bigger than water and alcohol and therefore too big to pass through the RO filter, this process shouldn’t affect the flavor of the wine. In theory (more on that later).

Spinning cone columns

Conetech is the Vinovation of spinning cone columns, which is to say that they’re pretty much the only player on their side of the high-tech dealcing business.

Spinning cone technology is nifty, if a bit abstruse-sounding. Wine (or another liquid) is passed over a vertical column of metal cones – spinning ones alternating with stationary ones – so that the wine spreads out into a very thin film on the surface of the metal. This allows for evaporation, but not everything in the wine evaporates at the same time. Volatiles (components with boiling points lower than water) including alcohol along with some aroma compounds evaporate first. Unlike traditional distilling, the process is done at reasonably low temperatures, a major advantage where wine quality is concerned. After the wine has been run through the column, it can be recombined with the “essence” – the volatile flavor molecules are captured off of the column in a separate fraction – along with however much of the alcohol is desired source.

Using less efficient yeasts

An up-and-coming technology for reducing alcohol during fermentation involves engineering yeast that make alcohol less efficiently. The great thing about this option is that it doesn’t require an extra processing step; the wine has less alcohol from the get-go, and there’s no risk of losing flavor or adding cost with dealcoholizing maneuvers.

Saccharomyces cerevisiae metabolizes (that is, eats) sugar and turns it into not only alcohol, but a bunch of other byproducts, too, including carbon dioxide, glycerol, acetaldehyde, and other flavor-affecting molecules. In the early days of commercial wine yeast production, beginning around the 1950’s, efficient conversion of sugar to alcohol was a desirable characteristic in yeast; winemakers usually wanted maximum bang out of fruit that was, in general, less ripe than it is today. But today’s riper fruit is propelling microbiologists to develop yeast that still eat as much sugar (so that wines still ferment to dryness) but produce more glycerol, for example, and less alcohol as a result. A major problem with this idea is that most of the other products yeast can make instead of alcohol have aromas and sometimes flavors that wine consumers are going to find off-putting (one option, acetoin, smells like rancid butter). Multi-step manipulations can eventually convert those icky-smelling chemicals into something innocuous, but the process ends up being more complicated and therefore harder to perfect source. A completely different problem is that these yeasts are genetically modified organisms (GMOs), and the use of GMO’s in winemaking raises some pretty heated hullaballoo from winemakers and consumers alike. Questions about GMO’s and issues with those troublesome, smelly byproducts are both reasons why none of these yeasts is yet on the market.

By the way, it’s a myth that wine yeast can’t ferment past 15% or 16% alcohol because they die of alcohol poisoning. In the era before commercial wine yeast, the wild yeasts that were, by default, responsible for fermentation hadn’t been specially selected for alcohol tolerance and might cop out at 14%. But commercial wine yeasts have been both selected and engineered for exactly that quality. Lallemand, a major Montréal-based yeast company, sells multiple yeast varieties with alcohol tolerances of 18% and even “18+.”

Removing alcohol during fermentation

It is, in theory, possible to remove alcohol during fermentation so that the yeast have a lower alcohol burden and ferment more efficiently, and so that the finished product contains less alcohol. Right now, though, the process remains in R&D; it still removes too many flavor compounds along with the alcohol to be commercially tenable.

It’s also possible to remove sugar from the must before initiating fermentation by using an enzyme called glucose oxidase (obtained from a mold) to convert glucose to gluconic acid, which yeast won’t ferment into alcohol. This method isn’t much used, though, because all of that extra gluconic acid can make the finished wine unpleasantly acidic source.

There are other ways of removing alcohol – dialysis (more membranes), freeze concentration (the same principle we all experienced as kids when our frozen juice boxes tasted weirdly watery at first and really concentrated at the end as it melted down), liquid CO2 extraction (neat, but expensive) – but for the time being, reverse osmosis and spinning cone columns are doing most of the work.

Reverse osmosis and spinning cone columns are by far the two most practical options for lowering alcohol levels (at least for large wineries.) It’s even possible for wineries to dealcoholize on-site, at the winery, if they’re approved as a “distilled spirits plant,” though the option is expensive enough that few wineries exercise it. Still, as I mentioned earlier, folks aren’t exactly shouting the good news from the rooftops. On the contrary, the rhetoric on Vinovation’s and Conetech’s websites suggests that they’re trying to make an unpleasant thing seem more pleasant. The marketing language on the Conetech website is pretty off-putting to this wine lover, with their contrast between the company’s “New Generation” wines and “conventional wines” known to the rest of the world, incidentally, as “wine.” The website for Vinovation, based in Sebastapol, does something similar; instead of offering dealcoholization services, they advertise “alcohol fine-tuning.” And Conetech – based in Santa Rosa and with “alcohol adjustment centers” in California, Spain, France, South Africa, and soon Australia – bills themselves as “the world leader in wine alcohol adjustment and flavor management” which “has also helped pioneer a whole ‘New Generation’ of lighter style wines.”

What dealcing does to wine quality is a tough question, since removing alcohol changes the character of a wine all by itself. Winemakers who object to dealcoholization argue that the extra processing step strips wine of its terroir, that je ne sais quoi that gives wine its charm (or so its supporters say.) It’s fair game to claim that the high alcohol itself is part of a wine’s terroir, since those alcohol levels say something about the local grape growing conditions. Multiple scientific studies show that all of the processing methods that involve taking something out of the wine inevitably take out flavor molecules along with the alcohol. And, evidence of flavor changes or no, the idea of “processing” wine is itself repulsive to plenty of winemakers and consumers; the “natural wine” movement is testament to that.

In the end, asking what you think about dealcing is much the same as asking whether you think that wine is an industrial food product or whether wine is art. If wine is just another food product, than all of these plastic membranes and metal cones aren’t a problem (tour a food factory sometime if you think the words “plastic” and “metal” don’t sound good next to “food”). But if wine is an art, if you really believe in that sunburnt vintner, then maybe there’s something wrong going on here. For myself, I’m happy to divide wine into the $8 mega-winery product I might open on a random Tuesday and the boutique bottle with a story and a sense of character. In my mind, those two bottles are so different from each other that they shouldn’t really share the same name (maybe “processed wine food,” the same way we call Kraft American slices “processed cheese food?”) Whether the mythical “everyone else” makes the same distinction might say a lot about how the dealcing industry will fare in the future. If anyone ever finds out about it, that is.

![By Valo at de.wikipedia [CC-BY-2.5 (http://creativecommons.org/licenses/by/2.5)], from Wikimedia Commons](https://www.palatepress.com/wp-content/uploads/2013/01/Flametail-623x400.jpeg)